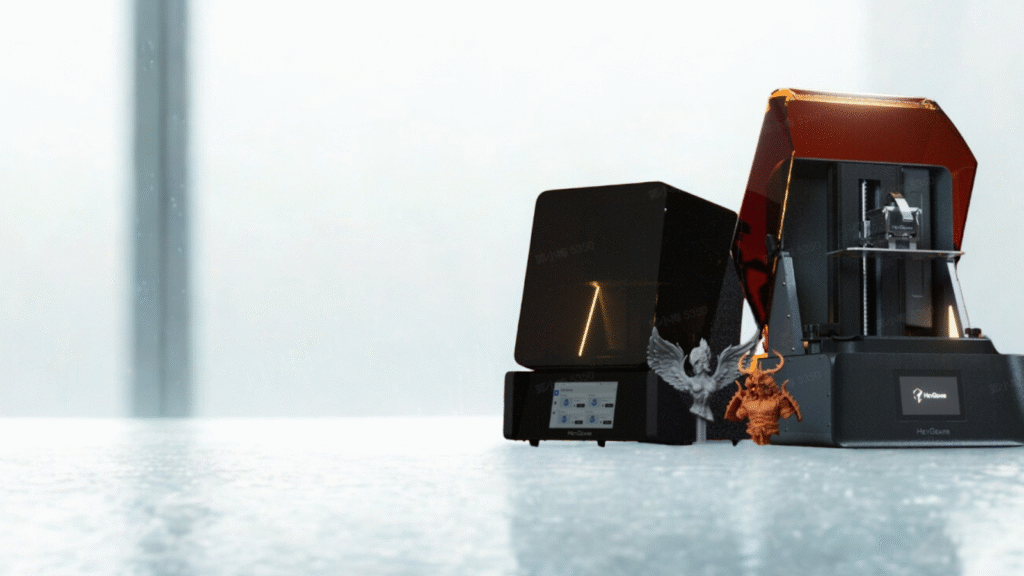

Resin 3D printing represents the pinnacle of accessible additive manufacturing, offering incredible detail and smooth finishes that bring digital designs to life with startling fidelity. Yet, the journey to consistently perfect prints can often be fraught with trial and error, calibration headaches, and messy post-processing. The dream of a seamless, dependable workflow, where advanced precision is simply a given, often feels just out of reach.

This guest post is for every enthusiast and professional who has grappled with the intricacies of resin printing. We’ll explore how an integrated approach, leveraging cutting-edge hardware, intelligent software, and purpose-built materials, can transform your printing experience, making reliability and precision not just aspirations, but repeatable realities.

Engineering for Excellence: The Foundation of Flawless Prints

The bedrock of any successful resin 3D printer lies in its mechanical integrity and optical precision. Achieving consistently high-quality results demands hardware that leaves no room for deviation, translating your digital model into a physical object with unwavering accuracy.

HeyGears resin 3D printers, such as the Reflex RS, are designed with this exacting standard in mind. They feature a C5 grade Z-axis module, which is engineered to ensure layer positioning errors are no more than 2 μm. This robust design is crucial, preventing minute vertical shifts that can compromise print quality, even when subjected to significant loads.

Furthermore, the optical system is meticulously calibrated. HeyGears employs full-field screen calibration across 60 zones, ensuring light intensity variation across the build plate remains within a tight ±3%. This precision directly translates to an impressive printing tolerance of ≤0.05 mm, ensuring that prints are true to your design. For those seeking even greater curing power, models like the Reflex Turbo incorporate a 385+ nm UV light source, delivering a 1.5 times more powerful resin curing effect compared to conventional 405 nm UV systems. Such dedicated engineering ensures every layer is cured uniformly and precisely, forming an unyielding foundation for your creations.

Mastering the Workflow: Intuitive Controls and Smart Processing

The true differentiator in modern resin 3D printing is how intelligently the process is managed. Gone are the days when painstaking manual adjustments were the norm. HeyGears are equipped with a suite of automated features and smart software to minimize human intervention and maximize success rates.

Before a single layer is cured, the printer prepares itself:

Floating Screen Auto Levelling: This system automatically corrects build plate alignment, capable of handling deviations up to 0.15° and eliminating gaps as large as 240 µm. This means perfect first-layer adhesion without tedious manual adjustments.

Automatic Resin Refill: Equipped with precise resin level detection (accurate within 5g), the printer can automatically replenish the resin tank before and during a print job. This prevents mid-print shortages and allows for uninterrupted, longer print runs.

Automatic Resin Heating: An optional heated resin tank can warm resin from 10°C to an optimal 22°C in approximately 20 minutes, then maintain this temperature for consistent results. This is vital, as resin viscosity changes with temperature, directly impacting print success and quality.

The intelligent design extends to the slicing software. HeyGears Blueprint software offers one-click slicing without manual adjustment and automatic repair for common model defects like inverse normals or holes. Its Intelligent Auto-Supports are specifically configured to reduce detachments and increase overall print success rates. During the print, real-time force sensors with 0.1 N sensitivity can detect resin residue as small as 0.2 mm or outright print failures, automatically pausing the process to prevent further issues and waste. Post-print analysis reports further aid in identifying and resolving any detected problems.

Precision Chemistry: The Role of Optimized Resins

While advanced hardware and software lay the groundwork, the choice of UV resin is paramount for the final properties and appearance of your resin 3D prints.HeyGears offers a diverse array of UV resin types, each engineered for specific applications:

- High-Stiffness, High-Precision Resins (e.g., PAH10 Black): With a tensile modulus of 3150 MPa and heat resistance up to 95°C, these resins are ideal for structural components, tooling, or parts demanding long-term deformation resistance.

- High Precise Detail Resins (e.g., PAP10): Tailored for intricate features, these resins can achieve a smallest pillar diameter of 0.1 mm with high fracture toughness, perfect for miniatures or finely textured surfaces.

- Water Washable Resins (e.g., PAWW10, PAWW20): Offering the convenience of 3-minute water washability and fast print speeds, these are excellent for rapid prototyping.

- Rigid Resins: The comprehensive range also includes ABS-like (PAU10) for high fracture toughness, flexible (PAF10) for repeated bending, and wax casting (PAC10) for lost-wax casting applications.

By choosing the appropriate HeyGears resin, you leverage a system where every component is harmonized, providing unparalleled control over the outcome. This ensures your resin 3D prints not only meet your aesthetic expectations but also perform precisely as intended.

In conclusion, the path to reliable and high-quality resin 3D printing is no longer a maze of endless troubleshooting. With an integrated ecosystem of advanced hardware, intuitive software, and precisely formulated resins, such as those offered by HeyGears, you can move beyond frustration and confidently achieve exceptional results with every print.

Keep an eye for more latest news & updates on Magazine!